fibre optic cable: Quick Guide to Fast, Reliable Networking

- Craig Marston

- Nov 19, 2025

- 13 min read

Fibre optic cable is the information superhighway of today’s networks. It channels data as pulses of light through strands of ultra-thin glass. That’s why organisations trust it for everything from office relocations to data-centre upgrades and high-bandwidth applications.

How Fibre Optic Cable Powers Modern Networks

Imagine data hurtling along hair-fine glass tubes—almost like bullets of light. The result? Massive volumes of information zip from A to B with negligible interference or delay.

Across the UK, fibre reach is accelerating. By January 2025, 74% of UK homes—equivalent to 23.68 million premises—were within reach of a Fibre-to-the-Premises (FTTP) network, up from 62% in January 2024.Discover more about FTTP coverage trends on ISPreview

Excel Network accredited partner for certified installation and ongoing support

25-year equipment warranty guarding against defects and performance dips

End-to-end testing to validate every connection before sign-off

Meticulous cable management that keeps desks and racks neat during moves

Rigorous equipment checks to guarantee reliability in relocations and fit-outs

Key Advantages For Businesses

Partnering with Constructive-IT means tapping into Excel Network accreditation—and all the confidence it brings.

Certified installation from an accredited partner reduces downtime by up to 30%.

By combining tidy cable runs with clear labelling, maintenance becomes a breeze and office moves stay on schedule.You might also find our guide on categories of network cables useful for your next project:Explore cable categories and the best choice for your project

Why Businesses Choose Fibre

Speed And Capacity – Supports gigabit-level performance for video calls, cloud services and rapid backups

Reliability – Immune to electromagnetic interference and harsh weather, keeping connections solid during moves

Future-Proofing – A 25-year warranty means the same cable grows with your bandwidth needs

These qualities turn fibre into an investment that pays off through consistent uptime and peak performance.

Next Steps For Your Network

Before diving into single-mode vs multi-mode, let’s make sure you’ve grasped the fundamentals. In the coming sections, we’ll cover:

How to choose between single-mode and multi-mode fibres

Criteria for matching cable types to your project

Expert tips for smooth, hassle-free installation

Along the way, you’ll discover why glass-core technology virtually eliminates electromagnetic hiccups, and how professional testing keeps your links within warranty standards. Stay tuned for a deep dive into the mechanics of fibre technology.

How Fibre Optic Cable Technology Works

Imagine data as a steady stream of water flowing through a clear tube that never leaks. Now replace that water with tiny pulses of light, and you start to see the magic of fibre optics.

At its heart, a glass core carries those pulses. Surrounding it is cladding with a slightly lower refractive index. Light enters at just the right angle, then bounces along the core walls without ever escaping—a phenomenon called total internal reflection.

This clever dance keeps signals sharp and intact, even when they travel over many kilometres without a repeat.

Key Components Of Fibre Design

Core: The light-carrying pathway made of ultra-pure glass that guides signals.

Cladding: A layer with a lower refractive index that traps the light inside the core.

Buffer Coating: Acts like a shock absorber, protecting against nicks and moisture.

Jacket: The rugged outer shell defending against abrasion, chemicals and environmental damage.

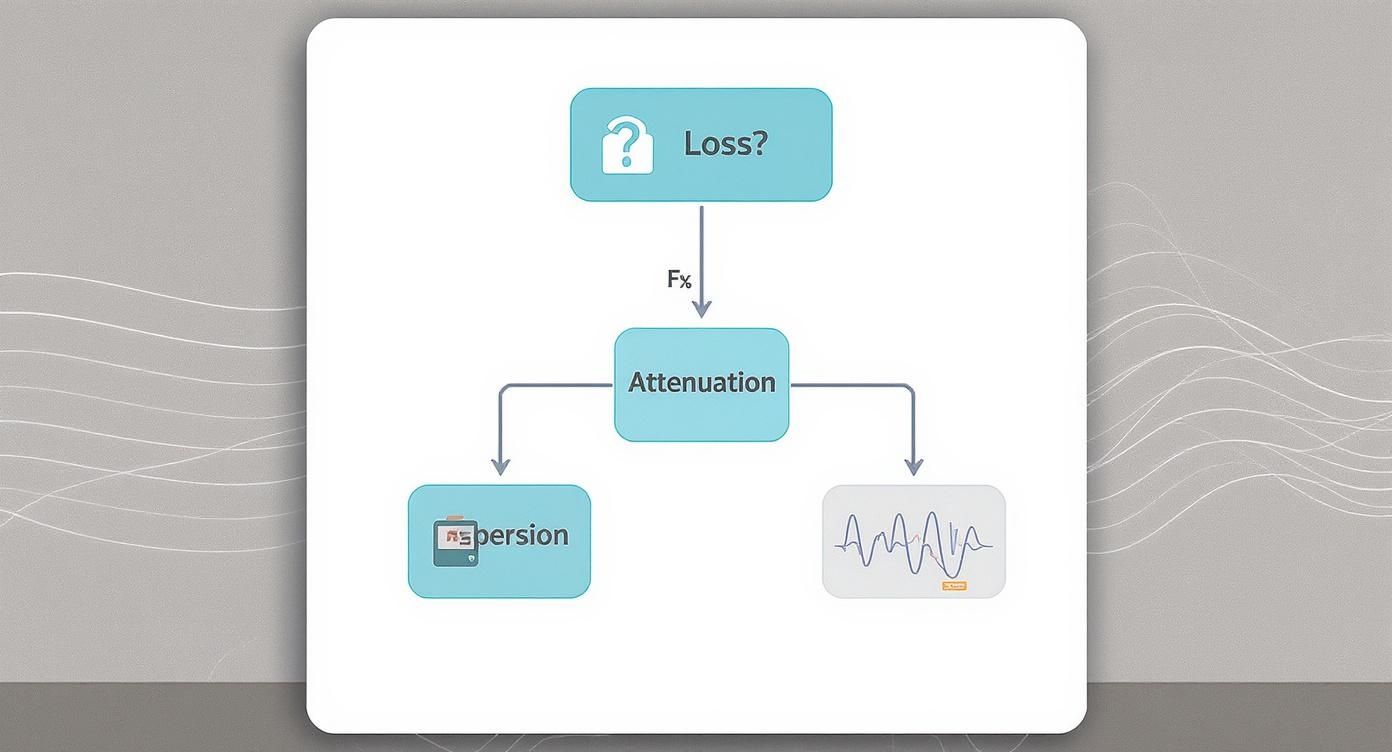

Together, these layers dramatically reduce attenuation—signal fade—by limiting energy loss. Yet, pulses can still spread or scatter if dispersion or microbending isn’t kept in check.

Modal Dispersion: In multi-mode cables, light can follow different paths, so some rays lag behind.

Chromatic Dispersion: Like a prism, varying wavelengths travel at slightly different speeds, stretching the data pulse.

Microbending Loss: Tiny bends in the fibre lead to light leaking out and weaker signals.

Manufacturing Techniques Reduce Loss

Producers polish each fibre end to a mirror finish, cutting down stray reflections. They also engineer graded-index profiles that smooth out modal dispersion and improve overall signal guiding.

Advanced fabrication holds the fibre diameter within micrometre tolerances. That precision limits microbends and keeps attenuation low.

Below is a quick comparison of typical loss figures:

Fibre Type | Wavelength | Attenuation (dB/km) |

|---|---|---|

Single-Mode | 1310 nm | 0.35 |

Multi-Mode (OM3) | 850 nm | 0.70 |

When it’s time to link fibre to your switches, Small Form-Factor Pluggable modules provide a neat, hot-swappable interface. Learn more about the versatility and uses for SFP optic modules on network switches

Why Fibre Outperforms Copper

A glass core can push data at over 200 Gbps, leaving copper cables far behind. It also ignores electromagnetic interference, so your network remains rock-solid even in electrically noisy environments.

Manufacturers run each cable through strict performance tests before shipping. That quality control means fewer surprises on installation day.

Real-World Fibre Applications

From corporate offices to sprawling data centres, fibre shapes modern networking:

Office Environments: Powers HD video calls, cloud backups and large file transfers with ease.

Data Centres: Offers high-density, low-latency links between servers, switches and storage.

Long-Haul Links: Uses low-loss single-mode fibre to bridge campuses or remote sites without repeaters.

These scenarios highlight why fibre outpaces copper in speed, reliability and future scalability. Plus, a 25-year equipment warranty delivers peace of mind for your infrastructure investment.

Next, we’ll explore how single-mode and multi-mode fibres differ—and how to choose the right type for your network’s exact needs. Stay tuned!

Comparing Single Mode And Multi Mode Fibre Cables

Fibre optic cable is a bit like a network of roads for data.Single-mode fibre resembles a single-lane expressway, engineered to carry massive bandwidth over great distances without congestion.

In contrast, multi-mode fibre feels more like a multi-lane suburban avenue, ideal for shorter hops around offices or campuses at a friendlier price point.

Key Features

Core Size: Single-mode fibre sports a 9 µm core, whereas multi-mode options generally offer 50 µm or 62.5 µm paths.

Distance Reach: You can stretch single-mode links beyond 40 km without repeaters. Multi-mode shines up to 550 m.

Equipment Cost: Transceivers for multi-mode run about 30–50 % cheaper, though single-mode modules justify their premium with extended reach.

Single Mode Vs Multi Mode Fibre Comparison

Below is a clear comparison table highlighting key characteristics for each fibre type.

Feature | Single Mode | Multi Mode |

|---|---|---|

Analogy | Single-lane express highway | Multi-lane suburban road |

Typical Use Cases | Long-haul links, metro backbones | Office networks, campus interconnects |

Launch Conditions | Requires laser sources, precise alignment | Uses LED or VCSEL, forgiving alignment |

Modal Dispersion | Negligible | Significant over longer runs; manageable on OM3/OM4 |

Cost Factors | Higher cable and module cost per metre | Lower installation and transceiver cost |

Use this snapshot to guide your choice between speed, distance and budget.

Launch Conditions And Dispersion

How light enters the cable—known as launch conditions—can make or break performance.

With single-mode, a finely tuned laser shoots a narrow beam straight down the core, keeping modal dispersion almost non-existent.

Multi-mode typically relies on LEDs or VCSELs, which are more forgiving but introduce multiple light paths that can arrive at slightly different times.

Modal Dispersion: Near zero in single-mode; reduced by graded-index design in multi-mode.

Chromatic Dispersion: Both types use optimised glass compounds to minimise wavelength spread.

Choosing The Right Cable

Your project’s distance, budget and performance goals dictate the decision.

For any run over 10 km, single-mode is almost always the smart pick. Under 300 m? Multi-mode often wins on cost and simplicity.

To ensure a flawless deployment, consider working with an Excel Networking Solutions accredited partner for installation, testing and certification.

Map out your link length and required bandwidth.

Compare module prices and per-metre cable costs.

Confirm compatibility with your launch sources and terminal devices.

Engage experts to install, test and certify your network under a 25-year warranty.

“Matching cable type to exact project needs optimises cost without compromising performance.”

Cost And Use Case Highlights

Budget considerations extend beyond cable alone—you must factor in transceivers and repeaters.

Single-Mode: Higher upfront cable and module costs, but fewer repeaters on long links.

Multi-Mode: Lower initial expense with LED/VCSEL transceivers—perfect for short runs under 300 m.

Office Fit-Outs: Neat cable management and multi-mode choices can slash installation time and overall spend.

By weighing these elements against your distance and speed requirements, you’ll land on the fibre type that aligns with both your performance targets and budget.

Choosing The Right Fibre Optic Cable

Picking the perfect fibre optic cable isn’t a one-size-fits-all decision. It’s about balancing the distance you need, the data volumes you’ll push through and the elements the cable must endure.

By getting these factors right upfront, you safeguard your 25-year equipment warranty and leave room for upgrades down the line.

Start by pinning down your project objectives before diving into technical details. Are you wiring a climate-controlled office? Laying cable through outdoor trenches? Each scenario calls for a different approach.

Just like choosing the right hiking boots, environmental stresses—think moisture, temperature swings or UV exposure—demand a sturdy jacket on your cable. While short office runs face fewer hazards, even indoor installations warrant careful planning. And with data demands climbing, opting for cables that outlast current speeds makes sense.

When your runs stretch beyond 300 metres, single-mode fibres usually win; under that threshold, multi-mode often suffices. Interestingly, full-fibre connections in the UK surged to 5.8 million by early 2025—a 13% jump quarter-on-quarter, thanks to Project Gigabit’s £1.3 billion injection.Learn more about fibre-optic manufacturing trends

Assess Your Project Needs

Break your decision into clear buckets to keep things straightforward:

Environmental factors such as moisture, temperature and UV exposure

Bandwidth goals for today’s network and tomorrow’s growth

Optimal run lengths to avoid signal drop and pricey repeaters

Future upgrades like 100 Gbps or 400 Gbps transceivers

With these criteria in hand, you can zero in on single-mode or multi-mode options.

Select Appropriate Cable Jacket

Different settings call for different jacket materials. For indoor racks, lightweight cables with flame-retardant, LSZH jackets are the norm. Outdoor trenches, on the other hand, demand armoured polyethylene sheaths that shrug off moisture and nibbling rodents.

LSZH for low-smoke indoor installations

Polyethylene armoured for direct-burial and outdoor trenches

Plenum-rated jackets for raised-floor air handling spaces

Choosing the right jacket isn’t just about performance—it preserves warranty and avoids fire-code conflicts. Don’t forget bend radius: over-bending introduces microbends that leak light and sap signal strength. Always respect the manufacturer’s minimum radius, usually printed on the jacket. In really tight corners, bend-insensitive fibres can be a lifesaver.

Check Bend Radius Requirements

Treat bend radius like a safety buffer. Always allow at least 20% extra margin above the cable’s stated limit.

Label pathways clearly to steer clear of sharp turns

Use angled adapters or trays for neat routing

Consider bend-insensitive fibre in compact installations

These simple steps keep your throughput high and your warranty intact.

Partner With Accredited Installers

Handing the job to an Excel Network accredited installer means certified workmanship and long-term support.

“Certified installations reduce downtime and deliver tested network performance under warranty.”

Accredited teams will carry out Tier 1 tests, OTDR traces and power-meter checks to validate every link:

Schedule a site survey to map cable routes.

Confirm your cable spec matches switches and transceiver modules.

Review test reports and securely store certification documents.

This approach protects your investment and maintains warranty compliance for decades.

Implementing Fibre Cable Installation Best Practices

Our Excel Network accredited partners specialize in fibre cable installation, delivering certified, tested network delivery with meticulous cable management to keep desks tidy during office relocations.

Laying fibre that endures begins with careful planning. A detailed site survey charts every route, turning unknowns into clear steps. That groundwork cuts surprises and saves time on the day.

Checking for tight bends, obstructions and exact distances keeps you within the bend radius limits and protects signal integrity from the outset.

Pinpoint sharp corners and add conduit where needed.

Measure runs accurately to estimate attenuation and position repeaters.

Record rack heights and desk layouts for seamless cable management during moves.

Conducting A Thorough Site Survey

A proper survey goes beyond tape measures. Note temperature, humidity and any environmental quirks that could affect the cable jacket and overall performance.

For instance, investigating raised floors often reveals hidden ducts or power lines. Spotting these early avoids electromagnetic interference and physical damage during installation.

“Accurate site surveys speed up installation and deliver more reliable networks.” – Constructive-IT Engineer Insight

Planning Cable Routing And Tray Layouts

Well-designed trays turn clutter into organised pathways. When trays are correctly supported, they prevent the microbends that harm optical performance.

Grouping cables by function and using colour-coded ties makes maintenance straightforward. Clear labelling ensures that anyone can trace a connection in seconds and keeps desks clutter-free during relocations.

Component | Purpose |

|---|---|

Patch Panel | Organises connectors for quick port access |

Splicing Enclosure | Protects splices and preserves signal |

Patch panels provide a central point for swaps without disturbing live runs. Splicing enclosures keep fusion and mechanical splices safe from dust and moisture, preserving low-loss performance and your 25-year warranty.

Clean each fibre end with lint-free wipes and isopropyl alcohol.

Align fibres precisely in the fusion splicer’s V-groove.

Secure the splice under a heat-shrink sleeve.

Connector cleanliness is non-negotiable. Even a speck of dust can push insertion loss beyond acceptable levels. Always inspect endfaces with a fibre microscope before activation.

Tip Clean connectors on every link to maintain 25-year warranty coverage.

Coordinating Testing And Documentation

After installation, validate each run with OTDR traces and power-meter loss tests. Compare those figures to your loss budget and industry standards.

This step unlocks your 25-year equipment warranty. Store test certificates, as-built schematics and photos in a central repository to streamline future audits or expansions.

Perform Tier 1 insertion loss checks against acceptance criteria.

Label each cable ID to accelerate troubleshooting.

Secure stakeholder sign-off following a go-live support session.

For more on designing optimal network pathways and rack setups, check out our guide on network infrastructure.

Including non-destructive digging methods like hydrovac excavation protects underground infrastructure; explore the benefits of vacuum excavation

Ensuring Dust-Free Handling And Connector Care

Dust and oils on endfaces spell trouble. Always use a proper cleaning kit and keep protective caps in place until you’re ready to connect.

Hands-on training helps technicians learn how to handle fibre gently and avoid scratches or microbends. Introducing live demos during office moves keeps workspaces tidy and connectors pristine.

Store spare pigtails in sealed, dust-proof cases.

Label cleaning tools and schedule regular maintenance.

Log every cleaning session to support warranty claims.

This approach maintains order on desktops and simplifies future upgrades. Partner with an Excel Network accredited installer to uphold warranty compliance and guarantee skilled workmanship.

Final Site Review And Approval

Conclude with a site walk-through alongside stakeholders. Confirm that trays, racks and desks are neat and every endpoint functions as intended.

Obtain written approval after all tests and inspections pass. Archive documentation—test logs, photos and diagrams—to back up any future expansions or warranty checks.

These steps deliver a fully tested network installation that meets industry standards and ensures minimal downtime with long-term reliability.

Top Takeaways• Conduct comprehensive site surveys• Plan rack and tray layouts meticulously• Prioritise connector cleanliness• Test every fibre path thoroughly• Document everything for 25-year warranty coverage

Embrace these practices to streamline fibre installs and build networks that stand the test of time.

Ensuring Warranty Coverage And Certified Network Delivery

Choosing an Excel Network accredited partner means your fibre installation not only follows best practices but also instantly qualifies for a 25-year equipment warranty. Certification is your guarantee that every segment of the network—from cable entry to patch panel—is inspected and signed off.

This rigorous process reduces unexpected downtime and keeps you clear of common warranty pitfalls.

Certified Installation Partner: Ensures consistent installation quality and fast-tracks warranty activation.

Tested Network Delivery: Optical loss tests and OTDR traces verify each fibre run.

Office Relocation Services: Equipment testing and cable management to ensure a smooth transition and tidy desk setups.

Performance Metrics: Detailed reports on insertion loss and reflectance.

Warranty Compliance: Paperwork aligns with Excel Network’s strict requirements.

Clean Work Areas: Technicians maintain tidy desk and rack spaces throughout installation and moves.

Relocations benefit from tested delivery, so every desk is ready to go the moment cables are reconnected. Professional certification reports then form the spine of your compliance records, giving IT managers a clear view of network health and any potential weak spots.

Interpreting Certification Reports

Certification reports list each fibre link by identifier, test date and measured loss values. These entries confirm that actual attenuation matches the planned loss budget.

If any measured loss creeps above the budget, technicians can immediately pinpoint the affected section for rework. That way, you avoid surprises at final sign-off and ensure optimal performance from day one.

Here’s a quick look at the warranty durations and certification services offered by Excel Network partners:

Equipment Warranty And Certification Features

Service | Description |

|---|---|

Tier 1 Test | Insertion loss and reflectance reports per fibre link |

OTDR Trace | Graphical distance-to-fault analysis highlighting anomalies |

Power-Meter Test | Quantifies optical power levels at specific wavelengths for accuracy |

As-Built Drawings | Detailed schematics showing cable routes, termination points and labels |

Whether you need a simple insertion-loss check or a full OTDR analysis, this table helps you align tests with contract and warranty conditions.

Performing Acceptance Tests

Acceptance tests are the final step before you trigger your 25-year equipment warranty. They confirm that the installation meets design goals and Excel Network standards.

Set pass/fail criteria based on your loss budget targets.

Run OTDR scans from both ends to uncover splices, connectors and bends.

Measure insertion loss with a power meter at 1310 nm and 1550 nm.

Compare results against manufacturer specs and industry guidelines.

Completing these steps gives you documented proof of network health, ready for stakeholder sign-off.

Step-By-Step Documentation Checklist

Tier 1 test certificates showing pass/fail statuses

OTDR trace files and graphical PDF reports

Power-meter logs detailing loss by wavelength

Final as-built drawings with cable routes and termination IDs

Clear photos of rack elevations and labelled panels

Storing everything in a central repository streamlines audits and expansions. It also helps you resolve warranty queries fast by proving installation quality.

“Thorough documentation is the key to unlocking the full benefits of your warranty and securing long-term support.” – Lead Engineer, Constructive-IT

Maintaining Warranty And Support Over Time

Your warranty doesn’t end after activation. Regular checks and audits keep performance on track and compliance intact.

Annual certification report reviews to spot drifts

Scheduled OTDR retests to verify link integrity

Connector and splice inspections with cleaning sessions

Working with our accredited support team ensures your 25-year equipment warranty stays valid through every move or upgrade. Our support portal gives you quick access to test logs, certification records and warranty documents—minimising desk clutter and maximising peace of mind.

Frequently Asked Questions On Fibre Optic Cable

Planning a fibre rollout can stir up a few familiar queries. Whether you're an IT engineer fine-tuning network performance or a facilities manager mapping out infrastructure, these FAQs zero in on the essentials.

Common Fibre Deployment Questions

What Are The Main Advantages Of Fibre Over Copper?

Imagine shifting data as effortlessly as water through a wide pipe. Fibre optic cable offers:

Higher Bandwidth for bulk transfers

Lower Latency so video calls feel instantaneous

EMI Immunity to shield against electrical interference

The result? Seamless HD conferencing, rapid backups and fewer network chokepoints.

How Do I Choose Between Single Mode And Multi Mode?

Think of single mode as a long-haul train and multi mode as a city tram. Use single mode when your runs stretch beyond 550 m or you need a robust backbone. For office or campus links under 300 m, multi mode hits the sweet spot on cost and performance.

Feature | Single Mode | Multi Mode |

|---|---|---|

Distance Reach | Over 550 m | Up to 300 m |

Typical Use | Backbones | Office and Campus |

Cost Efficiency | Higher | More Affordable |

Which Certification Tests Are Essential After Installation?

Proper certification is like a health check for your network. Key tests include:

Visual Inspection to catch visible flaws

OTDR Tracing for precise distance and fault locating

Power-Meter Loss Testing to measure signal attenuation

Make sure you receive comprehensive test certificates—each link must be validated.

“Certified testing by an Excel Network accredited partner guarantees tested network delivery and activates your 25-year equipment warranty.”

How Does The 25-Year Warranty Protect My Investment?

A quarter-century warranty is more than a sticker—it’s peace of mind against performance dips and manufacturing faults. Under specified conditions, any defective component gets replaced at no extra cost.

Neat desk and rack installations ensured by certified workmanship

Streamlined cable management for future moves and expansions

On-site equipment testing during relocations to minimise downtime

Installation And Warranty Checks

Schedule detailed site surveys and label each cable for clarity

Review OTDR and insertion loss reports regularly to uphold warranty terms

Constructive-IT offers expert fibre optic cable deployment, certified testing and a 25-year equipment warranty. Get in touch at Constructive-IT for a reliable network you can trust.