Your Essential Guide to UK Cat6 External Cable Installations

- Craig Marston

- 2 days ago

- 16 min read

A Cat6 external cable is a tough-as-nails network cable built specifically to handle the great outdoors. It's designed to deliver reliable, high-speed connectivity between buildings or to external devices, no matter what the weather throws at it. Unlike the standard cables you find indoors, it has a durable, weatherproof jacket that shields it from moisture, UV rays, and temperature swings, ensuring your network performance doesn't dip when the elements take a turn.

Why Outdoor-Rated Cabling Is Your Network's First Line of Defence

Think of your organisation's data network as its central nervous system. For commercial buildings, hospitals, or during a complex office move, this system has to be robust, reliable, and completely secure. While your internal cables manage the data traffic buzzing within the walls, the Cat6 external cable acts as the armoured backbone connecting your core infrastructure to the outside world.

Standard indoor cables just aren't up to the job. Exposing them to the UK’s notoriously damp climate and unpredictable temperatures would cause them to degrade quickly, leading to flaky connections and, eventually, total failure. That's why specialised outdoor cabling isn't a luxury—it's a fundamental requirement for modern business continuity.

Extending Your Network Beyond the Walls

The need for durable external connectivity is everywhere you look in a modern commercial setting. It's the critical link for:

Connecting adjacent buildings: Creating a single, unified network across a business park or campus.

Outdoor security systems: Reliably powering CCTV cameras and access control points.

External Wi-Fi access points: Providing seamless coverage in car parks or outdoor communal areas.

Linking to remote equipment: Ensuring solid communication with external generators, HVAC units, or monitoring systems.

These jobs all demand a connection that performs flawlessly, day in, day out, regardless of the weather. Using the wrong type of cable is one of the most common—and costly—data network mistakes we see. To avoid it, you need to understand the different categories of computer network cables and what the best choice is for your data networking project.

Investing in Future-Proof Infrastructure

Putting your money into high-quality external cabling is really an investment in your operational future. The demand for resilient, high-performance network infrastructure is growing fast across the UK, part of a nationwide push towards digital modernisation. In fact, the UK Ethernet cable market is projected to grow at a compound annual rate of 10.2% between 2023 and 2030, driven by major strategic initiatives. You can explore more data on this significant market expansion.

For mission-critical environments like hospitals or large commercial sites, this investment goes beyond just buying cable. It means partnering with certified professionals who can actually guarantee performance. As an Excel accredited partner, for instance, we can deliver a fully tested and certified network, complete with a 25-year equipment warranty. This certification is your assurance that every connection is robust, reliable, and ready to support your organisation's needs for decades to come, providing true peace of mind.

Choosing The Right Type of Cat6 External Cable

Getting the right Cat6 external cable from the very start is one of those decisions that prevents a world of future pain, from flaky connections to the eye-watering cost of ripping it all out and starting again. For anyone in charge of network installations, whether it's for a commercial building or a hospital, picking the correct cable is the foundation of long-term reliability. Get it wrong, and you've just undermined your entire infrastructure.

The first big question you need to answer is whether to use unshielded or shielded cable. This choice comes down entirely to the electrical environment where your cable will live.

Unshielded vs Shielded Cables

An Unshielded Twisted Pair (UTP) cable is the go-to for most everyday networking jobs where there's no significant electromagnetic interference (EMI) to worry about. The clever twisting of the wire pairs inside the cable does a decent job of cancelling out low-level background noise.

However, the moment you plan to run a cable near anything that generates serious electrical noise—think high-voltage power lines, big industrial motors, transformers, or even banks of fluorescent lights—you absolutely need a Shielded Twisted Pair (STP) or Foiled Twisted Pair (FTP) cable. These cables have a layer of metallic foil or braiding that acts like a suit of armour, shielding the data signals from disruptive EMI. When you're mapping out your cabling runs, applying effective network design strategies is what separates a robust network from a problematic one.

Jackets And Armour for Outdoor Survival

Beyond the internal shielding, it’s the cable's outer jacket and construction that truly decide if it can handle the great outdoors. Your standard indoor cable usually has a PVC jacket, which is fine inside but will quickly go brittle and crack when blasted with UV sunlight and fluctuating temperatures.

For any external run, you need a cable with a tough Polyethylene (PE) jacket. This material is built to resist UV rays and moisture, giving you a solid first line of defence. If the cable is going into a duct or any area that might get damp, you need to step it up again with gel-filled or dry-core cables. These contain a special water-blocking compound that stops moisture from creeping down the cable if the outer jacket is ever nicked.

Then there's the toughest job of all: direct burial. For this, an armoured Cat6 external cable is the only game in town. This cable has a layer of Steel Wire Armour (SWA) under its jacket, offering serious protection against being crushed or accidentally sliced by a spade during groundwork.

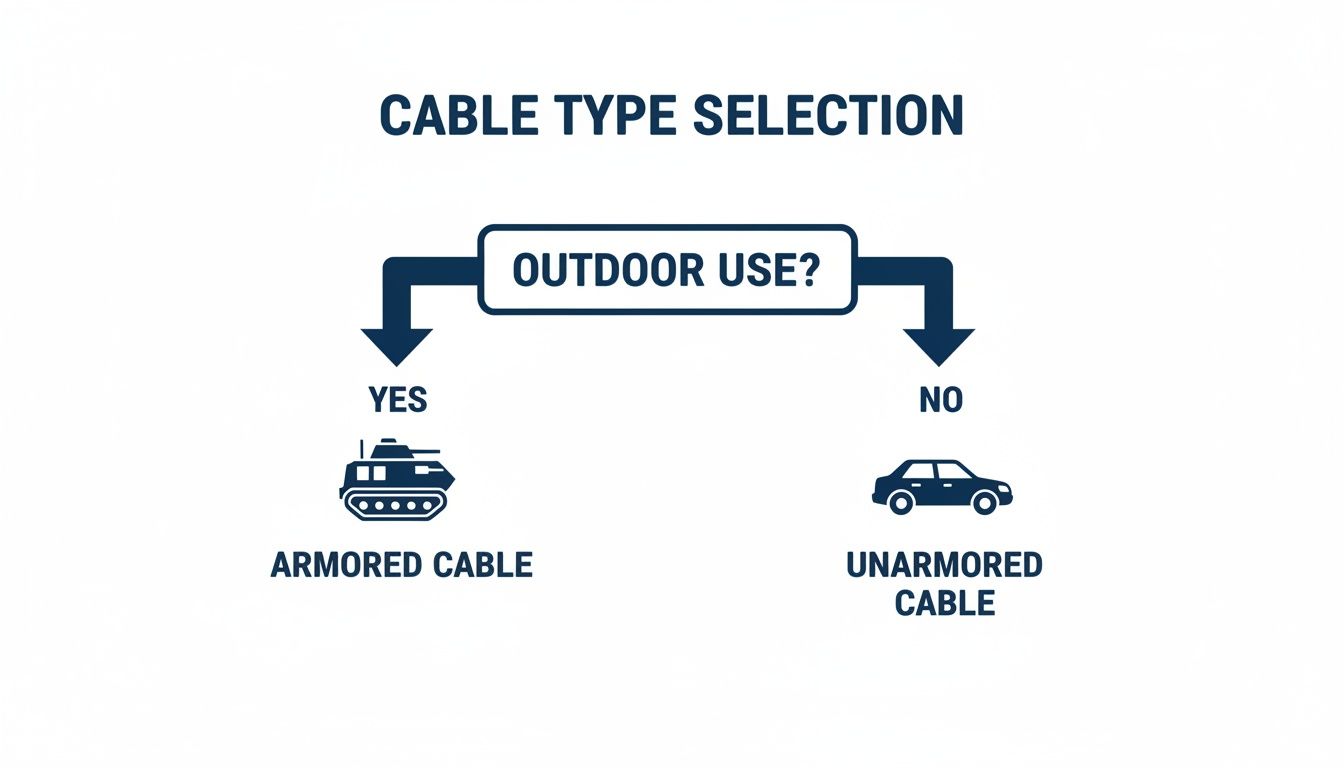

This simple flowchart breaks down the fundamental choice between standard indoor cables and their much tougher, armoured outdoor cousins.

As you can see, the moment your plan involves running a cable outside, you immediately need to shift to a more robust, specialised cable to ensure your network has any kind of longevity.

Making The Right Specification

To help you visualise the options, the table below compares the key features of each external Cat6 cable type.

Comparison of Cat6 External Cable Features

Feature | UTP (Unshielded Twisted Pair) | STP/FTP (Shielded/Foiled Twisted Pair) | Armoured (SWA) | Best Use Case |

|---|---|---|---|---|

EMI Protection | Basic (from twists only) | High (foil/braid shield) | High (shielding + SWA) | Running alongside power cables or heavy machinery. |

Moisture Resistance | Dependant on jacket (PE) | Dependant on jacket (PE) | Excellent (PE Jacket + SWA) | Ducts, damp areas, or direct burial. |

Physical Protection | Low | Low | Very High | Direct burial, high-risk industrial environments. |

Jacket Type | PVC (Indoor) or PE (Outdoor) | PE (Outdoor) | PE (Outdoor) | Outdoor runs with UV exposure. |

This table makes it clear that there's no one-size-fits-all solution; it's all about matching the cable's specs to the challenges of its environment.

The growing demand for faster, more dependable networks has made Cat6 the undisputed industry standard. The global Cat6 cable market hit USD 10.27 billion in 2024 and is expected to rocket to USD 17.48 billion by 2033—proof of its superior performance.

Picking the right specification isn't about over-engineering for the sake of it. It's about accurately matching the cable's protective features to the real-world risks it will face. A cable clipped neatly along a sheltered wall has very different needs from one buried two feet under a car park.

To nail the decision every time, just run through this checklist:

EMI Exposure: Is the cable path anywhere near heavy machinery or high-voltage lines? If the answer is yes, you need shielded (STP/FTP).

Moisture Levels: Will the cable be sitting in a duct that could fill with water? If so, you need a gel-filled or dry-core spec.

Physical Risk: Is the cable being buried, or could it be crushed or hit? If there's any doubt, Steel Wire Armour (SWA) is non-negotiable.

Getting these details right is fundamental to building a network that just works. For a deeper dive into the basics, have a look at our essential guide to Cat 6 cable, which covers the core concepts in more detail.

Avoiding Common and Costly Installation Mistakes

Investing in a premium Cat6 external cable is a great start, but it’s only half the battle. The real-world performance and lifespan of your network hinge entirely on the quality of the installation. Even the best cable on the market is useless if it’s put in poorly.

For commercial buildings and hospitals, where network reliability is absolutely non-negotiable, sidestepping these common but costly blunders is fundamental to success. A professional installation is a meticulous process, one that respects the cable’s physical limits and shields it from the environment. It's how you build a network that’s robust, compliant, and ready for whatever you throw at it next.

Respecting the Physical Limits of the Cable

Every Cat6 cable has a minimum bend radius – a limit on how tightly it can be bent before the delicate copper pairs inside are damaged. Think of it like kinking a garden hose; you choke the flow. Forcing a data cable around a sharp corner can permanently wreck its internal structure, leading to signal loss and intermittent faults that are an absolute nightmare to track down.

Always stick to the manufacturer's specified bend radius, which is typically four times the cable's outer diameter. This tiny detail is one of the most common reasons networks fail certification tests. It’s a simple rule, but it protects your investment right from the start.

The other essential layer of defence is conduit. Running an external cable without this protective shield is like sending an armoured vehicle into a battle without its armour. Conduit protects the cable from everything: accidental spade strikes during future groundwork, nesting rodents, and the slow, relentless wear-and-tear of the elements.

Professional installers understand that a data cable is a high-performance component, not a simple piece of wire. Every bend, pull, and termination must be executed with precision to preserve its integrity. This is the difference between a network that merely works and one that is certified to perform flawlessly for decades.

Preventing Electronic 'Noise' and Interference

One of the sneakiest threats to your data is electromagnetic interference (EMI), often just called electronic 'noise'. This is generated by high-voltage power cables, large motors, transformers, and even fluorescent lighting. If a Cat6 external cable is run too close to these sources, the EMI can corrupt the signals travelling through it.

To stop this, the golden rule is physical separation. Data cables should be run at least 30 centimetres (12 inches) away from any parallel high-voltage power lines. If they absolutely have to cross, they should do so at a sharp 90-degree angle to minimise the window of interference.

In crowded plant rooms or service risers where keeping your distance is tricky, using a shielded (STP/FTP) cable is the answer. But a word of warning: a shielded cable is only effective if it's correctly grounded at one end. Get the grounding wrong, and you can accidentally turn the shield into an antenna, making the interference problem even worse.

A few key rules for dodging EMI:

Keep your distance: Run data and power cables in separate trays or conduits whenever you can.

Cross at right angles: Never run data and power lines parallel to each other for long stretches.

Use a shielded cable: In high-EMI areas, make STP or FTP cable a mandatory requirement.

Get the grounding right: The shield must be terminated and grounded properly at the patch panel to drain away interference. If you're unsure how to terminate it correctly, our guide on the Cat 6 connectors diagram offers clear, visual instructions.

Managing the Critical Outdoor-to-Indoor Transition

Bringing a Cat6 external cable from the outside of a commercial building to the inside isn't as simple as drilling a hole. This transition point is governed by strict UK building and fire safety regulations, and getting it wrong is a serious compliance failure.

The tough, outdoor-rated PE jacket on an external cable is not typically fire-rated for internal use. Because of this, regulations often demand that the cable is terminated within a short distance (usually a few metres) of entering the building. From there, the connection must be continued using an appropriately fire-rated internal cable.

What’s more, any hole drilled through an external wall must be properly sealed with fire-stopping materials. This is a critical life-safety measure that prevents fire and smoke from racing through wall cavities. Neglecting this during an office relocation or hospital fit-out can lead to failed building inspections, costly rework, and serious safety risks. A certified installer, such as an Excel accredited partner, will always ensure these transitions are fully compliant, delivering a network that is not only high-performing but safe.

The Real Meaning of a Tested and Certified Network

That little green light blinking on a network port? It's reassuring, but it's also one of the most misleading signs in IT. It tells you there's a basic electrical pulse, nothing more. It says absolutely nothing about the quality, speed, or reliability of that connection.

For any business that depends on its network—which is every business—relying on a link light is like judging the structural integrity of a new bridge by looking at a picture of it. You need to know it can handle the traffic at full speed without crumbling. The only way to get that guarantee is through a professional, certified network delivery.

Going Beyond a Simple Continuity Check

Many installers stop at a basic continuity check, often done with a cheap wire-mapper. This just confirms that each of the eight tiny wires in the cable connects to the correct pin on the other end. It’s a good first step for spotting simple wiring mix-ups, but it’s completely blind to the performance-killing issues that plague poorly installed networks.

A full certification test, on the other hand, is a completely different beast. It’s a rigorous examination using sophisticated equipment like a Fluke Network Analyser. This machine blasts high-frequency signals down the cable and measures precisely how they behave, comparing the results against internationally recognised TIA/ISO standards. This is the only way to prove a cat6 external cable can actually support Gigabit or 10-Gigabit speeds reliably.

"Certification isn't just a final step; it's the ultimate proof of quality. It transforms the installation from a collection of cables and sockets into a guaranteed, high-performance asset that the business can rely on for years to come."

What a Certification Report Actually Tells You

When a certified engineer hands you a certification report, it's not just a piece of paper. It’s a detailed health check of your network's physical layer, providing pass/fail results on critical performance metrics that expose the true quality of the installation.

Understanding these key metrics is crucial:

Attenuation: Think of this as signal fade. It measures how much the signal weakens over the length of the cable. Too much loss, usually from exceeding the 100-metre limit or using cheap cable, means dropped connections and flaky performance.

Near-End Crosstalk (NEXT): This checks for signal 'bleed' between the wire pairs right at the connection point. It's almost always caused by untwisting the wires too much during termination, and it leads directly to data corruption.

Return Loss: This identifies signal reflections, which are like echoes bouncing back down the line. These are caused by badly fitted connectors or sharp kinks in the cable, and they create chaos for data flow, causing errors and re-transmissions.

A clean sweep of 'PASS' results means your network isn't just "working"—it's performing precisely as engineered. This certified delivery is how a professional avoids the common data network mistakes that can cripple a business.

The Link Between Certification and Warranty

For professional installers, certification is absolutely non-negotiable, and it’s all tied to the warranty. As an Excel accredited partner, we can provide a 25-year equipment warranty on the structured cabling systems we install. But that powerful guarantee is only validated once the entire network has been meticulously tested and certified.

This process ensures that every single link—from the patch panel in the comms room to the socket on the wall—meets the strict performance standards set by the manufacturer. It’s your definitive proof that the job was done right, the materials are top-notch, and the network is ready to support your organisation for the long haul.

Ultimately, a certified network delivery isn't an optional extra. It’s your peace of mind, backed by a decades-long warranty.

Why Professional Cable Management Matters

After all the hard work of choosing, installing, and certifying a cat6 external cable network, it’s the final finish that tells the real story. Professional cable management is so much more than just making things look pretty; it's a direct reflection of the quality and expertise poured into the entire project.

A chaotic spaghetti mess of cables behind a server rack isn't just an eyesore—it’s a ticking time bomb for maintenance headaches. In mission-critical environments like hospitals and busy commercial buildings, a meticulously organised network is fundamental to operational stability and safety.

The Foundation of Long-Term Reliability

Proper cable management starts with using the right tools for the job. Forcing cables around sharp corners or leaving them hanging unsupported puts physical stress on the delicate conductors inside. Over time, that strain leads to signal degradation and the kind of intermittent network faults that are an absolute nightmare to track down.

That’s why professional installers rely on specific containment systems:

Cable Trays and Trunking: These create a dedicated, protected highway for your cables, shielding them from being crushed and ensuring they never bend too sharply.

Velcro Ties Over Plastic: Cheap plastic zip ties are a false economy. It’s far too easy to overtighten them, pinching the cable and wrecking its performance. Velcro ties offer a secure but gentle grip.

Strain Relief: Securing cables properly where they connect to patch panels and outlets means an accidental tug won’t disconnect or damage the sensitive termination points.

This structured approach doesn’t just protect the network’s integrity. It makes future moves, adds, and changes incredibly straightforward, saving a huge amount of time and money down the line.

Bringing Clarity to Complexity

In a large installation with hundreds of connections, a clear labelling system isn't just a 'nice to have'—it's essential. Without it, trying to troubleshoot a single faulty port can become a day-long expedition, tracing anonymous wires through ceilings and walls. A professional installer puts a logical labelling system in place at both the patch panel and the wall outlet.

This simple act of organisation is invaluable, especially during an office move or a system upgrade. When an IT manager can instantly see which port connects to which device, problems get solved in minutes, not hours, and network downtime is kept to a minimum.

A tidy network is a reliable network. The discipline of professional cable management directly translates into enhanced performance, simplified maintenance, and a safer working environment. It demonstrates a commitment to quality that builds confidence for years to come.

The Impact of a Tidy Desk and Workspace

The principles of good cable management extend all the way to the user's desk. A 'tidy desk' policy, where cables for monitors, docks, and network points are routed neatly, makes the whole office look more professional and feel safer. It gets rid of trip hazards and stops those accidental disconnections that can kill productivity.

For projects like hospital upgrades, this attention to detail is even more critical. Clean, organised cabling cuts down on dust build-up and makes cleaning easier—a vital consideration in any healthcare setting. As an Excel accredited partner, we know that delivering a fully tested and certified network is only half the battle. The final presentation—the visible proof of meticulous care—is what provides the ultimate peace of mind and proves the long-term value of the investment, often backed by a 25-year equipment warranty.

Partnering with a Certified Installer for Peace of Mind

Let's be honest, tackling a cat6 external cable installation might look tempting as a DIY job. But when it comes to commercial buildings or hospitals, the stakes are just too high. A small oversight isn't just a minor hiccup; it can quickly spiral into a major data network failure, causing anything from frustratingly slow connections to a complete system outage that brings your entire operation to a standstill.

That kind of trouble leads to costly rework, project delays, and a whole lot of operational headaches. A certified installer is your insurance policy against all of that. They bring the expertise to plan the project properly, specify the right materials, and follow strict installation standards to make sure your network performs perfectly from the moment it's switched on. It's not just about avoiding problems—it's about building a rock-solid digital foundation for your organisation.

The Value of an Excel Accredited Partner

Choosing an installer with a specific accreditation like Excel adds another, even stronger, layer of security. As an Excel accredited partner, our job goes far beyond just running cables from A to B. We’re trained and regularly audited to deliver a fully tested and certified network, which guarantees every single component meets the highest performance standards. This certification isn't just a piece of paper; it's tangible proof that your installation is free from defects and ready to handle the data loads you need it to, no compromises.

This is absolutely vital for big projects like an office relocation with equipment testing, where you simply can't afford any network downtime. A certified partner handles the whole process, from the initial fibre cable installation for the high-speed backbones right through to the final 'tidy desk' finish, making the transition seamless. On larger projects, like a new build or a full guide to commercial building renovation, getting the right professional partners on board is critical to your success.

Securing Your Investment with a 25-Year Warranty

This is probably the single biggest advantage of working with an Excel accredited partner: access to a 25-year equipment warranty. This isn't something you can get by just buying the parts off the shelf. It’s a long-term guarantee that only gets activated once the entire installation has been professionally certified. It's the manufacturer's promise that your network is built to last.

This warranty transforms your cabling from a simple operational expense into a protected, long-term asset. It provides unparalleled peace of mind, knowing that your investment in critical network infrastructure for a commercial building or hospital is secure for decades.

You simply can’t get this level of assurance without a certified professional. From meticulous cable management that makes future maintenance a breeze to the rigorous testing that proves every connection is perfect, every step is designed to deliver a network that's not just fast and reliable today, but future-proof and protected for tomorrow.

External Cat6: Your Questions Answered

When you're planning a network that has to brave the great outdoors, a few common questions always pop up. Here are the straight answers to the queries we hear most often from IT and facilities managers planning reliable infrastructure for demanding environments like commercial sites and hospitals.

Can I Just Run My Regular Indoor Cat6 Cable Outside Through a Conduit?

This is one of the most tempting—and most costly—mistakes you can make. The short answer is no, absolutely not.

Standard indoor Cat6 cables have a PVC jacket, which simply isn't built for the outdoors. It will break down when exposed to moisture, UV rays, and fluctuating temperatures. Even tucked away inside a conduit, condensation is inevitable. That moisture will slowly but surely destroy the PVC jacket, leading to signal failure and a network that's dead in the water. Always, always use a cable with a proper PE (Polyethylene) jacket designed for the job.

What's the Furthest I Can Run an External Cat6 Cable?

Whether it's indoors or out, the rule for Cat6 is the same: the maximum channel length is 100 metres (328 feet). This isn't just the cable itself; it's the total length, including the patch leads at each end.

Pushing past that 100-metre limit is asking for trouble. You'll get signal degradation, packet loss, and an unreliable connection. If you need to cover more ground than that, the right tool for the job is a professional fibre cable installation. Fibre can handle high speeds over massive distances without breaking a sweat.

Do I Really Need to Get My External Cable Installation Certified?

Yes, a thousand times, yes. Professional certification isn't just a nice-to-have; it's the only way to prove your new cabling actually performs to the strict standards it's supposed to. It's your guarantee that the installation is physically sound and ready for business.

Crucially, it’s also a non-negotiable requirement for activating any long-term manufacturer warranties. For example, as an Excel accredited partner, our installations unlock a 25-year equipment warranty. Without that certified report from a professional tester, you have no proof of performance, no warranty, and no assurance that your critical network will deliver the speeds you paid for.

For a network that's professionally planned, flawlessly installed, and certified to perform for decades, partner with Constructive-IT. Find out how we can support your next project at https://www.constructive-it.co.uk.

Comments