Cable Ties Mounts (cable ties mounts): A Guide to Flawless Network Installations

- Craig Marston

- 2 days ago

- 16 min read

That messy tangle of cables lurking behind a desk or inside a server room is more than just an eyesore. It’s a genuine business risk, a ticking clock that can lead to frustrating downtime and costly data network mistakes. Professional cable management, held together by components as simple as high-quality cable tie mounts, is the absolute bedrock of a commercial network you can count on. These small but mighty parts are what make sure your entire infrastructure is secure, ready to scale, and built to perform.

Why Professional Cable Management Is Non-Negotiable

When you look at a chaotic server rack or a jumble of wires at a workstation, you’re not just seeing a lack of tidiness. You're seeing a fundamental weakness at the physical layer of your network. In high-stakes environments like commercial buildings and hospitals, where network failure simply isn't an option, meticulous cable management becomes a non-negotiable standard of quality. It's the difference between a certified, high-performance asset and a disaster waiting to happen.

This structured approach is about so much more than just making things look neat. It’s about engineering a system where every single component plays its part in delivering long-term reliability.

The Foundation of Network Performance

Think of your network’s physical infrastructure like the foundation of a building. You wouldn't dream of putting a skyscraper on shaky ground, so why would you run a mission-critical network on disorganised cabling? In this analogy, cable tie mounts are the structural anchors holding that foundation together.

They are absolutely essential for a few key reasons:

Preventing Signal Degradation: Properly secured cables, especially delicate fibre optics, are held at their optimal bend radius. This simple act prevents the signal loss and data corruption that can bring a network to its knees.

Simplifying Maintenance and Upgrades: When cables are neatly routed and secured, technicians can easily find, trace, and replace what they need without causing a major disruption to the whole system.

Enhancing Safety: Let's be honest, loose cables are tripping hazards. They can also create serious fire risks if they get damaged or overheat near power sources.

Upholding Warranty Standards: A certified network installation, like one that comes with an Excel 25-year equipment warranty, has to follow strict installation rules. Proper cable support is a huge part of that.

Getting your professional cable management right is a cornerstone of overall IT efficiency and feeds directly into the wider conversation around comprehensive IT asset management best practices.

Avoiding Common Data Network Mistakes

So many of the most expensive network errors don't come from complex software bugs, but from poor physical installation. Unsecured cables get snagged during an office relocation with equipment testing, pulled by accident during routine cleaning, or just slowly degrade from the constant strain of their own weight. Using the right cable tie mounts from day one eliminates these preventable risks.

A network’s performance is only as strong as its physical foundation. Investing in professional cable management is an investment in reliability, ensuring every connection is tested, certified, and built to last.

The demand for these robust solutions is only getting bigger. With UK data centres expanding by 25% since 2020, the need for proper fibre optic organisation has gone through the roof, and effective mounting has been shown to reduce signal loss by up to 22%. This is all part of a much bigger trend in the UK's cable management market, which is being driven by massive infrastructure investments. If you want to learn more, check out our guide on why hiding power and data cables matters.

Choosing the Right Cable Tie Mounts for Your Project

Picking the right cable tie mounts is one of those small details that makes a huge difference in a structured cabling project. It’s easy to overlook, but getting this wrong can lead to sagging cables, network dropouts, and can even put your 25-year equipment warranty at risk. This decision is about much more than just keeping things tidy; it’s about guaranteeing the physical integrity of your network for decades.

Think of it like this: an adhesive mount is like a bit of sticky tape. It’s quick, easy, and perfectly fine for light, temporary jobs on a clean surface. A screw-down mount, on the other hand, is a structural bolt. It’s engineered for permanent, heavy-duty support in commercial buildings, data centres, and hospitals. Choosing correctly from the start is what prevents those costly network mistakes down the line.

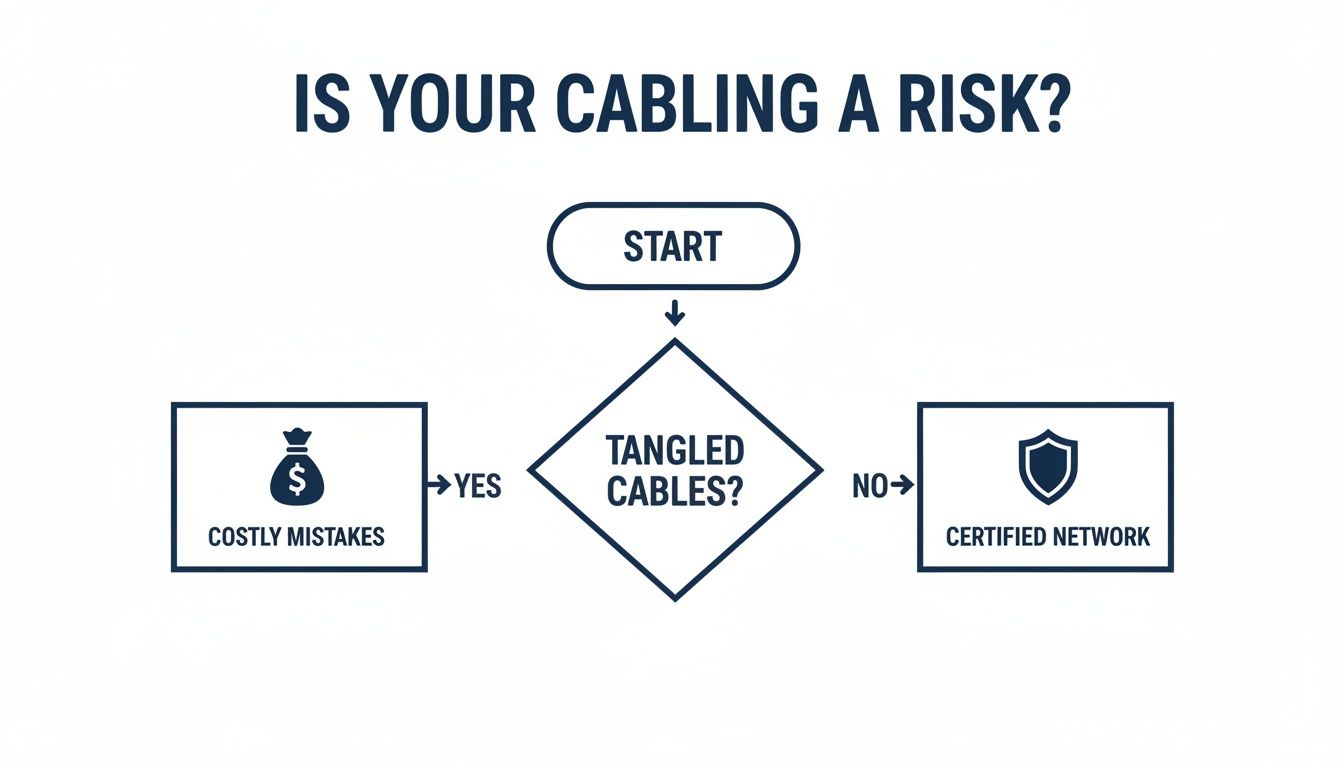

The decision tree below really drives home the risk of cutting corners on cable management.

As you can see, what starts as a few tangled cables can quickly spiral into expensive problems. A professionally managed system, however, leads directly to a reliable, certified network you can count on.

Adhesive Mounts: A Cautious Approach

Adhesive-backed mounts are undeniably convenient for quick fixes or achieving a tidy desk. You just peel and stick, no tools needed, which makes them a go-to for light-duty home and office use. For a clean desk setup, they often do the job just fine.

But in a professional setting, that convenience comes with some serious drawbacks. The adhesive bond is only as good as the surface it's stuck to—it needs to be perfectly clean, smooth, and non-porous. In the real world of commercial buildings, with painted plasterboard, textured walls, or dusty server rooms, these mounts are just waiting to fail. The weight of multiple data cables, combined with temperature swings, will eventually weaken the bond until the mount peels away, leaving your cabling dangling.

Screw-Down Mounts: The Professional Standard

For any permanent installation in a commercial environment, screw-down mounts are the industry standard. In fact, they’re the only option we recommend for securing primary cable runs. These mounts are mechanically fastened directly to the structure, whether that’s wood, metal, concrete, or plasterboard, creating an anchor point that is exceptionally strong and permanent.

This method completely removes the risk of failure, guaranteeing the mount can handle the weight of heavy cable bundles for the life of the installation.

Unmatched Reliability: Once they’re in, they stay in. Environmental factors like heat, dust, or humidity won’t affect them.

High Load Capacity: They are specifically designed to support the significant weight of large copper and fibre cable bundles without sagging.

Warranty Compliance: Using screw-down mounts is a non-negotiable requirement for meeting the strict installation standards needed to validate an Excel 25-year network warranty.

This mechanical fixing is what ensures your cable management system remains robust and secure for the entire lifespan of your network.

The choice between an adhesive and a screw-down mount is fundamentally a choice between a temporary fix and a permanent solution. For mission-critical infrastructure, there is no substitute for a mechanical fixing.

Specialised Mounts for Unique Challenges

Of course, it’s not always a straight choice between stick or screw. Certified engineers have a whole toolbox of specialised cable tie mounts to solve specific installation challenges. Push-mounts, for instance, have a built-in pin that simply pushes into a pre-drilled hole, offering a fast and secure fixing in panels or server racks.

In situations where drilling just isn’t an option, like on structural steel beams or in temporary setups, magnetic mounts can provide a surprisingly strong yet non-permanent solution.

To give you a clearer picture, here’s a quick guide to help you select the right mount for the job.

Cable Tie Mount Selection Guide

This table provides a quick comparison to help you choose the right mount based on your specific application, load capacity, and the surface you're working with.

Mount Type | Best Use Case | Load Capacity | Ideal Surfaces | Key Consideration |

|---|---|---|---|---|

Adhesive | Light-duty, temporary, home/desk use | Low | Smooth, clean, non-porous (metal, plastic) | Prone to failure with dust, texture, or weight over time. |

Screw-Down | Permanent, mission-critical, commercial runs | Very High | Wood, plasterboard, metal, concrete | Requires tools for installation but offers total reliability. |

Push-Mount | Fastening to panels, enclosures, server racks | Medium | Pre-drilled holes in sheet metal or plastic | Quick installation, but requires a pre-existing hole. |

Magnetic | Steel beams, server cabinets, temporary setups | Medium-High | Any flat ferrous metal surface | Strong but non-permanent; can be repositioned easily. |

Ultimately, the key is to have a professional partner who knows how to assess the environment and specify the correct component for every part of the installation. This is especially true for more complex routing where solutions like raceways come into play. For a deeper dive, you might want to explore our guide on raceways for cables for safe and scalable network wiring. This expertise is what ensures a properly tested and certified network delivery.

How Material Choice Impacts Longevity and Safety

The type of mount you choose is important, but the material it's made from is just as critical. In controlled environments like server rooms or hospitals, this decision can be the difference between a reliable network and a disaster waiting to happen. Think of the mount's material as its DNA—it dictates exactly how it will behave under stress, heat, and the simple passage of time.

Getting this wrong can lead to premature failures that compromise your entire infrastructure. A brittle, snapped mount might seem like a small detail, but it can become a significant point of failure. Making the right choice is fundamental to long-term reliability. It ensures the physical foundation of your network remains solid for years, safeguarding your fibre cable installation and upholding the conditions of a 25-year equipment warranty.

Standard Nylon 6/6: The Everyday Workhorse

Pop the bonnet on most standard installations and you’ll find Nylon 6/6. It’s the go-to material for a reason. This general-purpose polymer is strong, flexible, and cost-effective, making it the default choice for indoor commercial jobs. In a climate-controlled office or data centre, it’s more than tough enough to secure Cat6 and fibre optic cabling without any issues.

However, you have to know its limits. Standard Nylon 6/6 wasn't designed for tough conditions. Leave it in direct sunlight or expose it to high temperatures, and it will eventually become brittle and fail. For any job that isn’t a standard, comfortable indoor setting, you absolutely must look at specialised alternatives.

Selecting a cable tie mount isn't just about what fits. It's about matching the material's properties to the specific environmental challenges of the site. This kind of foresight prevents costly data network mistakes and is essential for certified performance.

Specialised Materials for Demanding Environments

Once your project moves beyond the four walls of a typical office, specialised materials are non-negotiable. An accredited partner will always specify the correct material based on a thorough site survey, ensuring the solution is genuinely fit for purpose.

Here are the key players for tougher jobs:

UV-Stabilised Nylon: If you're mounting anything outdoors, from CCTV cameras to rooftop antennas, this is the only sensible choice. It contains additives that shield the polymer from the damaging effects of ultraviolet radiation, stopping it from becoming brittle and cracking in the sun.

Heat-Stabilised Nylon: Got a mount near heavy machinery, HVAC units, or inside a poorly ventilated cabinet? This is what you need. It’s formulated to withstand constant high temperatures without losing its strength, ensuring your cables stay put.

Plenum-Rated Materials: In air-handling spaces (plenums), fire safety rules are incredibly strict. Mounts made from low-smoke, zero-halogen (LSZH) or other plenum-rated polymers are mandatory. These materials don't release toxic fumes in a fire—a critical safety feature in commercial buildings.

Choosing the right material ensures every single component of your network is tested, certified, and safe.

The Impact on Network Reliability and Warranty

Ultimately, the stuff your mounts are made of has a direct, measurable effect on network uptime. In the UK, cable tie mounts have become indispensable for IT infrastructure projects, from office fit-outs to full-scale relocations. Using the correct mounts to support high-speed networks has been shown to slash physical failure rates by up to 30%. What’s more, neatly organised wiring makes maintenance and troubleshooting far easier, which can cut ongoing costs by as much as 18%. You can discover more insights about the cable tie mount market to see how this trend is shaping installations.

Using the wrong material is also one of the fastest ways to void your 25-year warranty. If a standard nylon mount fails due to UV exposure and causes a fibre optic cable to bend and break, that failure won't be covered. A certified network delivery means every single component, right down to the humble cable ties mounts, meets the strict specifications for the environment it’s installed in.

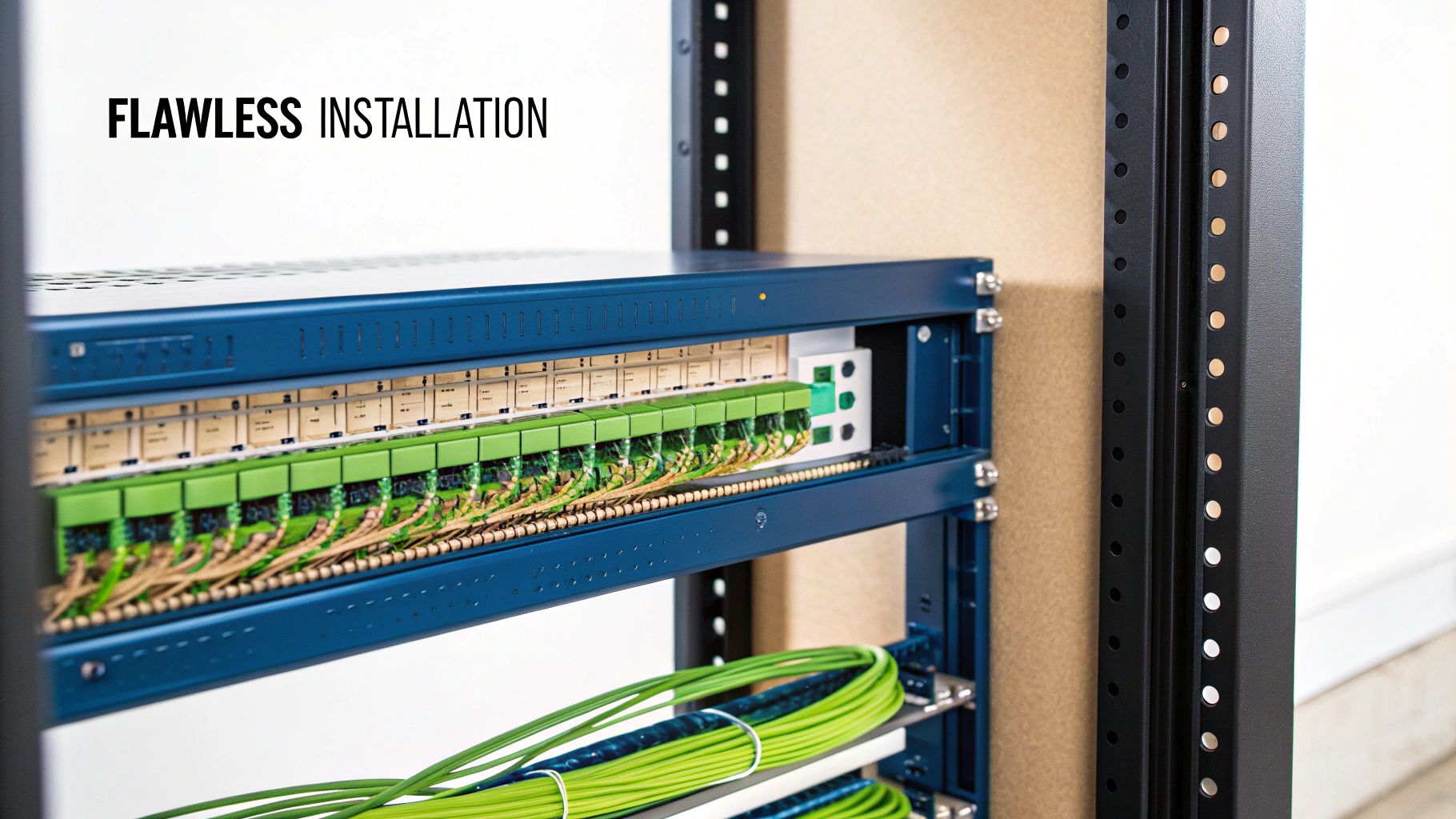

Best Practices for Flawless Installation and Routing

Having the right cable tie mounts and materials is only half the battle. What truly defines a professional network is the precision of its installation. It's the meticulous routing and securing of every cable that elevates a pile of components into a high-performance, reliable system that’s built to last.

This isn’t just about making things look tidy. It’s about creating a clean aesthetic that actively supports peak performance. During any large-scale project, whether it’s a full office relocation or a new commercial fit-out, certified engineers apply specific techniques to ensure the infrastructure is flawless from day one.

Planning Your Cable Pathways

Before a single mount goes on the wall, the first step is always strategic planning. A classic rookie mistake is just running cables along the most direct path without thinking about the surrounding environment. An experienced engineer knows better and plans routes to sidestep common sources of trouble.

Effective pathway planning involves:

Avoiding Electrical Interference: Data cables, especially copper ones, should never be run parallel to high-voltage electrical conduits. This simple separation prevents electromagnetic interference (EMI), which can corrupt data signals and cause those frustrating, intermittent network drops that are a nightmare to diagnose.

Considering Future Access: Routes have to be planned for easy access down the line. Tucking cables away in inaccessible ceiling voids or behind permanent fixtures turns future maintenance or upgrades into a costly and disruptive headache.

Mapping for Scalability: A well-planned installation always anticipates future growth. By leaving plenty of space in cable trays and pathways, you ensure that adding new lines later on doesn’t mean ripping out everything and starting again.

This kind of foresight is the hallmark of an accredited partner and is fundamental to building an infrastructure that can evolve with your business.

Ensuring Correct Spacing and Tension

Once the route is mapped out, the physical installation of the cable tie mounts can begin. The spacing of these mounts is absolutely critical to the long-term health of your cabling, particularly for horizontal runs where gravity is a constant enemy.

If you space mounts too far apart, you’ll get cable sag. This puts unnecessary physical stress on the cables and their connection points. Over time, this strain can degrade performance and lead to connection failures. As a rule of thumb for most data cabling, a mount should be placed every 30-50 cm to provide adequate support and prevent sagging.

Strategic mount placement isn’t just about tidiness; it’s a foundational practice that prevents performance degradation, simplifies future maintenance, and is essential for passing the rigorous tests required for a 25-year equipment warranty.

Protecting Delicate Fibre Optic Cables

When you’re working with fibre optic cables, the level of care required goes up another notch. Unlike tough copper wiring, fibre is made of glass and is incredibly susceptible to damage from improper handling. The single most critical factor is maintaining the correct bend radius.

If you bend a fibre cable too sharply, you create micro-fractures in the glass core. This allows light to escape and leads to significant signal loss, a problem known as attenuation. Every cable has a manufacturer-specified minimum bend radius, and a professional installation ensures this is never violated. Cable tie mounts are positioned strategically at corners to create gentle, sweeping curves rather than sharp, damaging angles.

This is a non-negotiable step for any certified and tested network. For a more detailed look at the specifics, our UK office network wiring installation guide provides some great insights. This meticulous attention to detail is what separates a professional, warrantied installation from an amateur one, ensuring every part of your network performs exactly as it should from day one.

The Critical Link Between Cabling and Network Certification

A perfectly organised server room is a beautiful thing, but if the network buckles under pressure, that neatness is just for show. This is where network certification comes in, turning a tidy installation into a proven, reliable business asset. Making sure your network is tested and certified is the crucial final step.

There’s an unbreakable link between meticulous physical work—right down to using professional cable ties mounts—and guaranteed network performance. A certified and thoroughly tested network isn't just a goal; it's the only acceptable outcome. It provides documented proof that every single link, from the data centre to the desk, meets the strictest performance standards. It’s not just a piece of paper; it’s an iron-clad assurance of reliability.

The Foundation of a 25-Year Warranty

When a network is backed by something like an Excel 25-year equipment warranty, it means the entire system has passed a battery of demanding tests. This certification is only awarded when every single component is installed precisely according to the manufacturer's guidelines.

Suddenly, seemingly small details, like using screw-down mounts instead of adhesive ones in a server rack, become critical prerequisites for that guarantee.

Installers have to prove that the physical infrastructure won’t get in the way of performance. This means:

No cable stress: Mounts must properly support the cable’s weight without putting any strain on the connectors.

Correct bend radius: Fibre optic cables need to be routed with gentle curves to prevent signal loss, which is a common but easily avoidable mistake.

Secure pathways: Every single run has to be firmly anchored to stop any movement or damage over time.

Failing to meet these physical standards is one of the most common reasons an installation fails its certification, turning a significant investment into a major business risk overnight.

From a Tidy Desk to Certified Performance

The road to certification starts with the absolute basics of cable management. An uncertified installation is a pure gamble. Sure, it might work fine on day one, but it lacks the verified resilience to handle the demands of a modern commercial building or hospital.

Intermittent dropouts, sluggish speeds, and baffling faults that are impossible to diagnose often trace back to a poor physical installation—a classic, and costly, data network mistake. A certified network, on the other hand, has been put through its paces to ensure flawless data transmission. The process confirms that the installation isn't just neat, but demonstrably reliable when it really matters.

Certification is the process that validates the quality of the physical installation. It proves that the network will perform as designed, protecting your investment and ensuring eligibility for a comprehensive 25-year warranty.

This focus on structured, professional cabling is being seen right across the industry. In the UK, the cable ties market, which relies heavily on cable tie mounts, is poised for major growth from 2026 to 2033. It's being driven by a booming construction sector valued at £150 billion annually. This trend highlights why smart businesses rely on end-to-end providers for everything from the initial survey right through to final certification.

Why Compliance and Certification Matter

Beyond just keeping things running smoothly, structured cabling plays a huge role in meeting regulatory standards. The proper organisation and routing of cables is a key part of preparing for and meeting network certification standards like SOC 2, which demonstrates a serious commitment to data integrity and system availability.

During a big project like an office relocation or a major fit-out, a certified installation gives you peace of mind that the new network is secure, compliant, and genuinely built to last.

This is exactly why working with an Excel network accredited partner is so crucial. They have the training, the tools, and the experience to ensure every aspect of the project—right down to the choice of cable ties mounts—is aligned with the high standards required for a fully warrantied and certified network. It’s the only way to be certain your network is truly ready for business.

Your Partner for Certified Infrastructure Projects

Bringing a complex network infrastructure project to life is all about getting the details right. From the big architectural decisions down to the specific cable tie mounts holding a fibre run in place, every single choice matters. These small components aren't an afterthought; they're the mark of a professional job and the final piece of the puzzle for a network that’s both tidy and tough. This is where having a true end-to-end partner really proves its worth.

Managing an office move or a new fit-out in a commercial building or hospital is a massive task. The last thing you need to be worrying about is the tiny details of the network delivery. By working with an accredited partner, you offload that whole process, from the initial designs and planning right through to the final, rigorous testing and certification.

The Assurance of a 25-Year Warranty

A 25-year equipment warranty from a provider like Excel isn't just a promise; it's a guarantee backed by documented proof of performance. To get this certification, every single part of the installation has to meet incredibly strict standards. This includes making sure all the cable management, especially the mounts securing the infrastructure, are correctly specified and installed. This meticulous approach stops common data network mistakes in their tracks and gives you total peace of mind that your investment is protected for the long haul.

Choosing a certified partner means you're not just buying a network. You're investing in a guaranteed, high-performance asset that has been professionally tested, validated, and built to last.

Your End-to-End Infrastructure Solution

For IT Directors and Facilities Managers, the goal is simple: a seamless project with a reliable outcome. As an Excel network accredited partner, we handle every stage of your fibre cable installation. We make sure your new network is not only cleanly installed and looks good, but is also fully tested and certified to perform flawlessly from day one. Our process is designed to deliver a future-proofed network that will support your organisation's goals without compromise.

If you're planning an office relocation, a new commercial build, or a network upgrade, don't leave the result to chance. Get the project done right the first time. Schedule a consultation with our certified engineers today to discuss how we can deliver a secure, warrantied, and high-performance network infrastructure built around your exact needs.

Your Questions About Cable Tie Mounts, Answered

When you're managing a commercial building project, whether it's an office fit-out or a new hospital wing, it's often the smallest details that spark the most important questions. This section cuts through the noise to give clear, straightforward answers about cable tie mounts for IT managers and facilities teams who need every part of their network to be rock-solid.

Getting these details right isn't just about being tidy; it's fundamental to building a network that performs flawlessly for years to come.

Are Adhesive Mounts Reliable for Permanent Installations?

While adhesive cable tie mounts are brilliant for a temporary setup or keeping cables neat at a desk, we never recommend them for permanent commercial installations. It's one of the most common data network mistakes we see. Over time, factors like temperature fluctuations, dust, and the simple, sustained weight of cable bundles will weaken the bond until it eventually fails.

For the kind of long-term reliability needed to back a 25-year equipment warranty, screw-down mounts are the only professional choice for primary cable runs. They create a solid mechanical fixing that guarantees stability, which is non-negotiable for any certified and tested network.

How Far Apart Should Cable Tie Mounts Be Spaced?

Proper spacing is vital for preventing cable sag. Sag doesn't just look untidy; it puts physical stress on the cable jacket and the termination points at either end. As a solid rule of thumb for horizontal runs of Cat6 or delicate fibre optic cables, spacing mounts every 30-50 cm gives you all the support you need to maintain performance.

However, if you're dealing with heavier bundles or running cables vertically where gravity is working against you, you’ll want to close that gap to 20-30 cm. As an Excel network accredited partner, our certified engineers calculate the precise spacing during the design phase to deliver a fully compliant installation built to last.

Can Using the Wrong Mounts Void My Network Warranty?

Yes, absolutely. A 25-year network warranty isn't just a piece of paper; it's a guarantee that the entire system has been installed according to strict manufacturer and industry standards. That includes every single passive component, right down to the cable tie mounts.

If a network fault is traced back to improper physical support—such as a failed adhesive mount causing a fibre cable to bend past its tolerance—it can void the warranty. This is precisely why a professional, certified installation is an investment in long-term protection and peace of mind.

Using cheap mounts that fail or installing them in a way that puts undue stress on the cables is a direct cause of performance issues. In high-stakes environments like commercial offices and hospitals, cutting corners on these foundational components is a risk that simply isn't worth taking. Every element has to be specified and installed correctly to ensure the network is not just tidy, but demonstrably reliable and fully protected.

At Constructive-IT, we ensure every component of your network infrastructure meets the highest standards for performance and longevity. Schedule a consultation today to guarantee your next project is backed by a certified, warrantied, and professionally managed installation.

Comments